SIMFUEL and Alpha-Active Material Manufacturing and Characterisation Facility

PI: Prof Tim Abram

The SIMFUEL and Alpha-Active Material Manufacturing and Characterisation Facility, located at the University of Manchester, is a world-leading laboratory for the manufacture and characterisation of a range of alpha-active nuclear materials. The NNUF facility consists of a Focussed Ion Beam Scanning Electron Microscope (FIB/SEM) coupled to an inert atmosphere glovebox and a Transmission Electron Microscope (TEM) dedicated to handling alpha-active materials. It is based within the Nuclear Fuel Centre of Excellence (NFCE) which gives users access to a wide range of sample manufacture, preparation, and characterisation techniques. This allows academic and industry users with an interest in alpha-active materials access to sample preparation and atom-scale microscopy to support research and technical problems across the nuclear fuel cycle, without the need to transfer material on and off nuclear licenced sites.

FIB/SEM – Helios 5 CX with Glovebox Autoloader

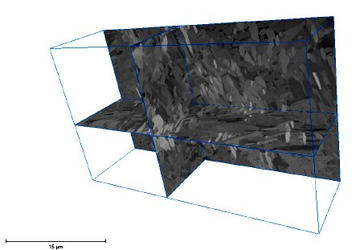

3D BSE images of Zr-Nb Alloy

© University of Manchester

The FIB/SEM is capable of electron and Ga ion beam imaging and milling of materials for the preparation of lamellae for further TEM analysis. The preparation of FIB lamellae allows the preparation of site-specific areas as well as the ability to dramatically size reduce samples for further TEM analysis so they can be handled more easily or even be sent to other institutes for analysis. The FIB/SEM is adapted for alpha-active material workflow, with a retractable sputter shield and is coupled to an inert atmosphere glovebox so the complete workflow can be undertaken without exposure of the user to alpha-active material. Furthermore, the facility is also capable of inert gas/vacuum transfer of the sample from the glovebox to the TEM to avoid exposure of the user to material and avoid exposure of the sample to air.

The microscope is equipped with Energy Dispersive X-ray spectrometry (EDS) and Electron Backscatter Diffraction (EBSD) which allows for chemical and crystallographic orientation/phase mapping. This allows the user to take FIB lamellae from specific regions in terms of chemistry or grain orientation. In addition, it is possible to perform BSE imaging, EDS and EBSD mapping with FIB milling to create and reconstruct 3D images as shown above.

Instrument specification:

• Electron column – 200 V - 30 kV Schottky FEG-SEM

• FIB column – 500 V - 30 kV Gallium ion Column

• EDS – Oxford Instruments 170 mm2 Ultimax

• EBSD – Oxford Instruments Symmetry detector

• Glovebox transfer for complete inert atmosphere contained workflow.

TEM – Talos F200i

The TEM is equipped with a high brightness field emission gun (X-FEG) capable of operating in both TEM and STEM modes. This permits the study of nanoscale features which is crucial for the study of nuclear fuel materials through their life-cycle and is capable of lattice and atomic level resolution alongside electron diffraction analysis. It is equipped with dual-EDS detectors and Electron Energy Loss Spectrometry (EELS) which can be used to determine chemical composition and oxidation states of the elements in the material. A range of holders are available for the analysis of samples at temperatures from ambient to liquid nitrogen, as well as surface tomography and 3D reconstruction.

Instrument specification:

• X-FEG electron source, 80-200 kV

• Dual EDS detectors (2 x 100 mm2)

• Gatan Continuum ER image filter

• Tomography holder and reconstruction software

• Cryogenic holder

• Inert gas/vacuum transfer holder to allow fully contained workflow.

Other alpha-active material manufacturing and characterisation equipment

Uranium glovebox suite for sample production and preparation

© Marc Schmidt

The instruments described above, which are directly funded by NNUF(2), are co-located within the NFCE which has additional capability to manufacture, characterise, and test samples containing uranium, thorium or higher actinides. The complete range of equipment is operated as a user facility through NNUF(2) and the Henry Royce Institute, providing a manufacturing, characterisation, and testing suite that can be used in combination with other NNUF facilities (e.g. the Dalton Cumbrian Facility) to perform beginning-to-end of life studies of nuclear fuel materials.

NFCE equipment at Manchester includes:

Spark Plasma Sintering Furnace with attached glovebox

© Marc Schmidt

• A suite of inert atmosphere gloveboxes for handling bulk quantities of uranic powders. These contain sample preparation facilities including mechanical/hydraulic pellet presses, automated polisher, slow speed saw and a tube furnace (1300oC) for non-oxide material synthesis.

• A suite of inert atmosphere gloveboxes for handling transuranic material in small quantities with a fully contained workflow including pellet pressing, a high temperature furnace capable of vacuum and reducing atmosphere operation up to 2400oC, Simultaneous Thermal Analysis (Netzsch STA 449 F3), Laser Flash Analysis (Netzsch LFA 427) and Dilatometer (Netzsch DIL 402 HT).

• NanoSEM 450 FEG-SEM equipped with EDS and EBSD detectors.

• A range of advanced fuel manufacturing techniques including arc-melting (Centorr 5SA), Spark Plasma Sintering furnace (Thermal Technologies 10-4), vacuum sintering (RD Webb Red Devil graphite furnace) and reductive sintering system capable of heat-treating uranium pellets in flowing hydrogen up to 1700oC.

• Chemical vapour deposition (CVD) and Hot-Isostatic Pressing (HIP) for the manufacture of TRISO coated particle fuels and compacts, using uranic kernels provided through collaboration within the NNL.

• Extensive suite of standard material analysis systems available for analysing alpha-active materials, including a Panalytical Empyrean XRD system, a Nikon HT220 tomography system, a Horiba XploRA Raman microscope, Micromeritics pycnometry and surface area testers, two Netzsch STA Jupiter F3s with steam generator system, and a broad range Netzsch thermo physics suite.

Availability

Electron optics

The alpha-active Talos S/TEM is currently available for pre-prepared specimens of depleted or natural uranium, and the Helios FIB-SEM/glovebox are expected to be available for May 2023 for uranic sample characterisation and preparation. The use of higher actinide containing samples will be introduced following active commissioning of the system and be subject to an appropriate risk assessment/safety case expected late 2023 to early 2024. For beta/gamma emitters we would suggest engaging with colleagues at UKAEA’s MRF facility in the first instance, but we are happy to discuss the use of low-activity or alpha-containing samples with a beta/gamma component on a case-by-case basis.

NFCE equipment

All other manufacturing and characterisation equipment listed at the NFCE is available for U/Th active work.

© University of Manchester.